High Pressure Grinding Rolls

CMC MG Series High Pressure Grinding Rolls has a large size feed opening and two large diameter opposite direction roating rolls which can have more space for Multi-layer crushing.

Moreover, CMC MG High Pressure Grinding Rolls applies not only in construction aggregates in producing cubic shape manufactured sand, but also well applies in asphalt and concrete for producing cubic shape manufactured sand too.

Feature

- Large diameter rolls to have sharp crushing angle which creates Multi-layer crushing. It manufactures best cubic shape product with the best FM value.

- Two rolls are imbeded with tungsten carbide cylinders. The high-density tungsten carbide cylinders are arranged to produce uniform-sized sand. The multi-point crushing design can produce the most cubic products.

- CMC High Pressure Grinding Rolls is using hydaulic system to keep constant discharge set. The feed material will be in Muti layer crushing between the two large rolls which can produce the most cubic products and minimize 200mesh below waste.

- Fixed rolls which are with replaceable flanges (imbeded with tungsten carbide plates) can make feed materials evenly distributed along the complete length of rollers, so that the rolls will be worn evenly and have the longest service life. The product quality will be stable and constant.

Application

- Construction Aggregates crushing sand

- Material shaping

- Concrete crushing sand

- Asphalt

Advantages

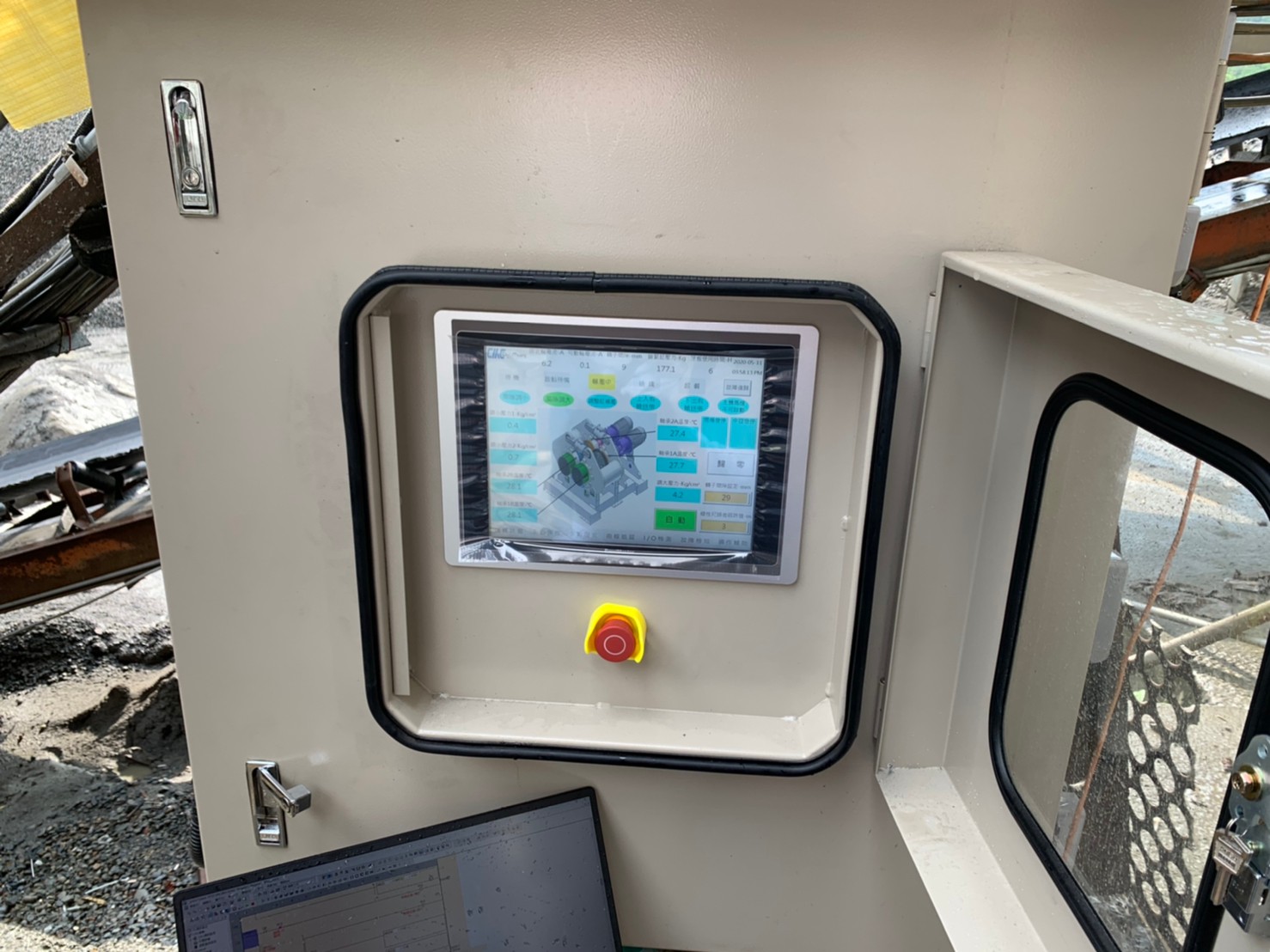

- With PLC system can control and keep same discharge set. The Product size is uniform, and capacity is stable.

- The unique flange design on fixed roll keep feed materials evenly distributed along the complete length of rollers, so that the rolls will be worn evenly and have the longest service life. The product quality will be stable and constant.

- Large diameter rolls with low speed can keep the bearings have the longer service life.